Can Data Save the Natural World?

With the current population figure exceeding 7 billion people, humans are draining the Earth of its resources which is putting immense pressure on the natural environment.

As a solution, many countries are now transitioning from a linear to a circular economy in order to reuse assets and minimize large amounts of industrial waste rendered useless during production.

In the manufacturing and building sectors, energy consumption is a major cause for concern, where heating, ventilation, air-conditioning, and refrigeration (HVACR) systems are responsible for up to 60% of energy consumption. What’s even more alarming is the fact that the European Union alone produces more than 2.5 billion tonnes of industrial waste per year.

The Manufacturing Industry’s Impact on the Environment:

- Increases energy consumption significantly

- Produces unwanted or potentially hazardous waste

- Causes pollution and damage to the air, soil, and water

- Increases CO2 emissions and harmful greenhouse gases

- Scarce raw materials and non-renewable resources are often wasted

If policymakers and organizations don’t lead the charge and change this approach, the world will soon be at a breaking point where it will lose the capacity to sustain itself.

The Solution — Replacing Traditional Models with a Circular Approach

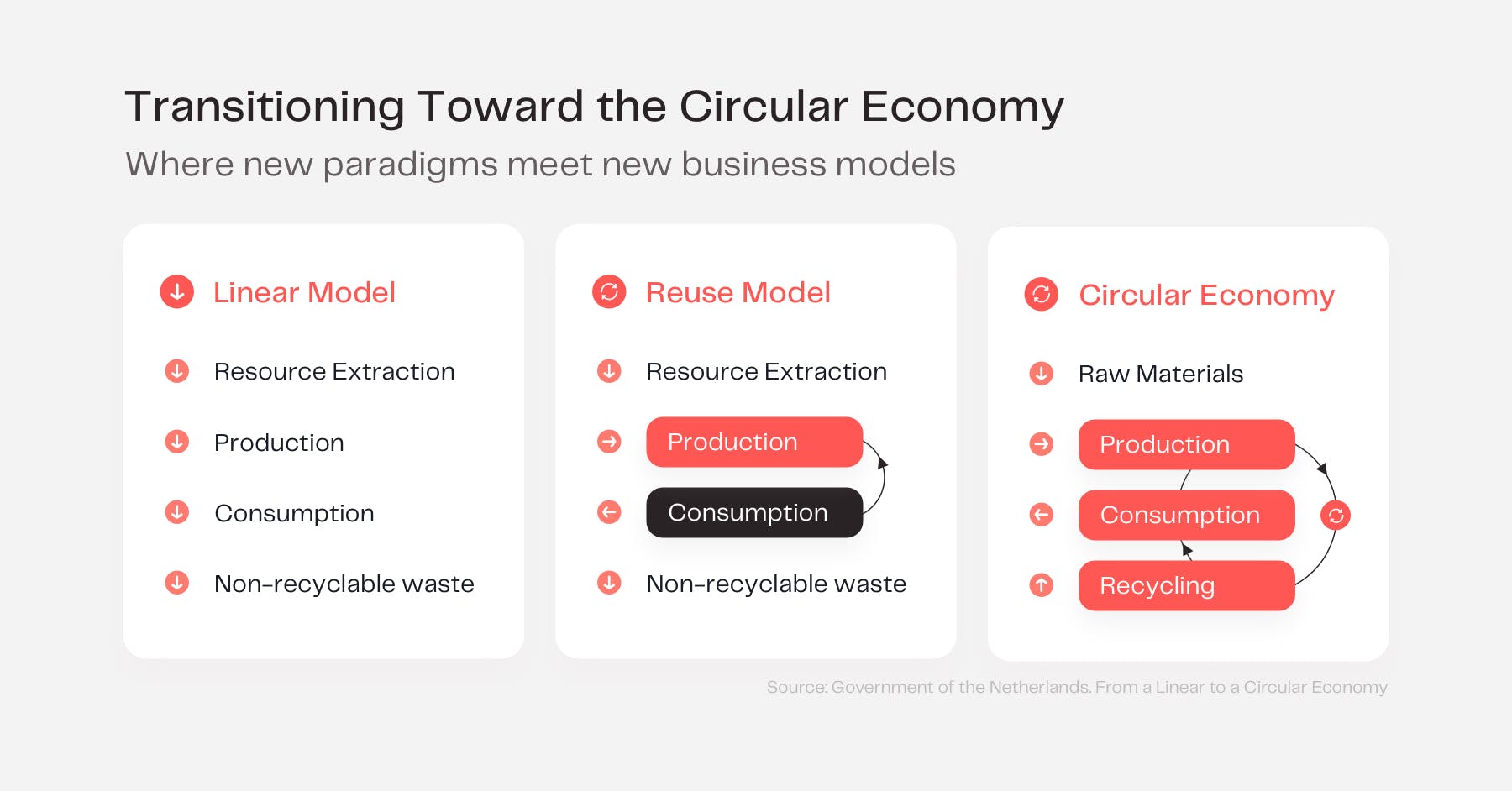

The traditional linear economy model is based on the take-make-consume-waste approach. In this model, raw materials and scarce resources are collected, transformed, and processed into products that are used until they are finally discarded as waste. The linear economy is an inefficient use of resources and a creator of unwanted and often dangerous waste.

In order to create a sustainable future for generations to come, a plausible solution to these challenges has finally evolved - the Circular Economy (CE). At its core, the circular economy is a system that is restorative and regenerative by design. The system aims to eliminate waste and follows a resource-conscious business strategy by protecting social, economic, and natural environments. A circular economy follows the 3R approach: reduce, reuse, and recycle with the overarching goal of designing out waste.

Built on the backbone of these principles, the main value drivers of the circular economy are: 1) extending the life cycle of resources; 2) optimizing utility and yield of resources; 3) creating additional use cycles for resources, and 4) increasing system efficiency and value by designing out negative externalities.

IoT Drives Sustainability and Unlocks New Value Streams

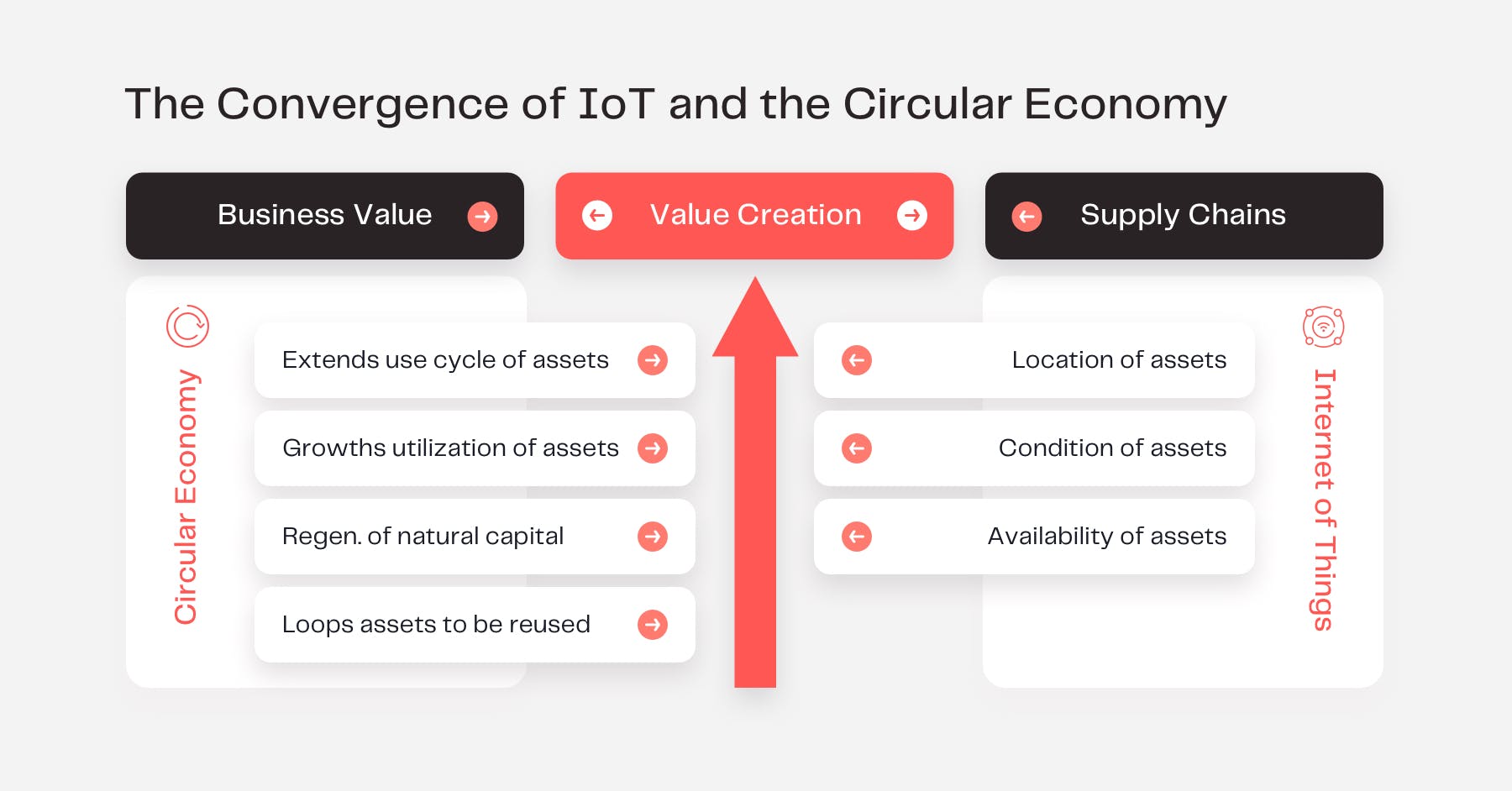

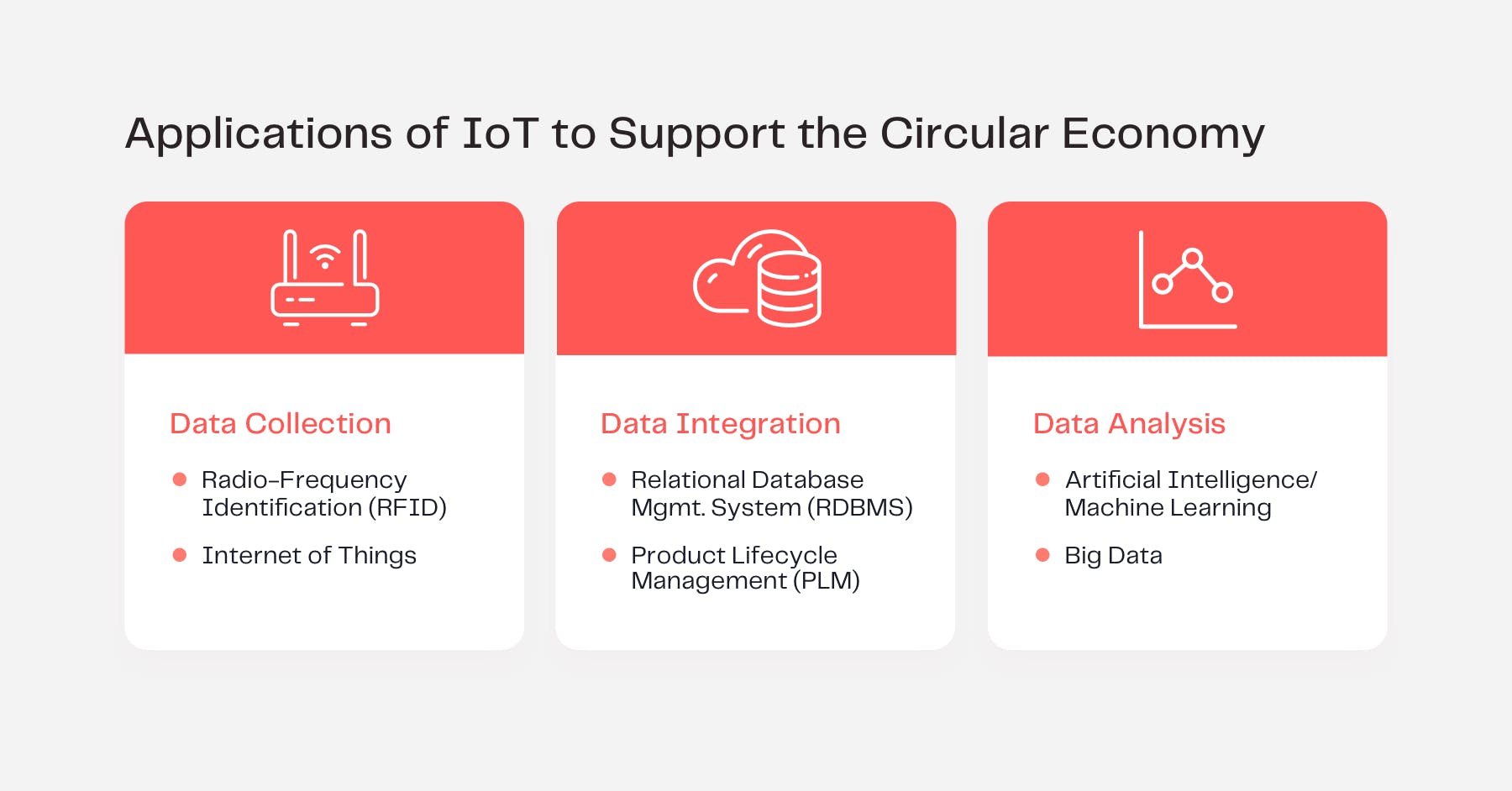

When circular economy models are combined with connected devices that gather unprecedented amounts of data, there’s an opportunity to use technology for the better — to conserve and protect natural resources, whilst promoting sustainable business practices.

Merging the CE with IoT creates an innovative framework that uses smart sensors, devices, and intelligent machinery to promote sustainability. The appeal to combining the CE with IoT is largely due to the benefits of having a network of smart devices: awareness, scalability, connectivity, security, intelligence, and autonomy.

Intelligent assets can sense, communicate, analyze, and store information about themselves and their surrounding environments. This creates a cohesive system where sensors can detect wasteful patterns and signal issues that arise, determine when repairs are needed, and schedule their own maintenance.

As a data-prolific and asset-intensive sector, the manufacturing industry has the potential to positively impact environmental conservation by reducing harmful emissions and waste.

Prioritizing Fit-for-Purpose Sustainable Supply Chains

The greatest improvements for corporate sustainability measures can be found in supply chains, which typically account for 80% of an organization’s greenhouse-gas emissions and more than 90% of its impact on air, land, water, and biodiversity. To put this into perspective, manufacturing and producing a single new smartphone takes as much energy as recharging and operating a smartphone for an entire decade. Unfortunately, the consumer electronics market remains one of the biggest culprits and contributors to harmful emissions and waste.

To combat this, the rise of IoT technologies presents new possibilities to monitor, analyze, and manage the carbon footprint across an organization’s supply chain in ways previously not possible.

Data gathered from connected sensors in the supply chain can more effectively manage the Earth’s finite resources and ultimately improve the manufacturing process from start to finish. Sensors provide businesses with real-time, insightful data, as well as historical data for more informed decision-making. IoT enables companies to track and monitor machine performance along the company’s production lines. This data provides insights to help companies improve overall equipment effectiveness (OEE) and energy usage per production unit.

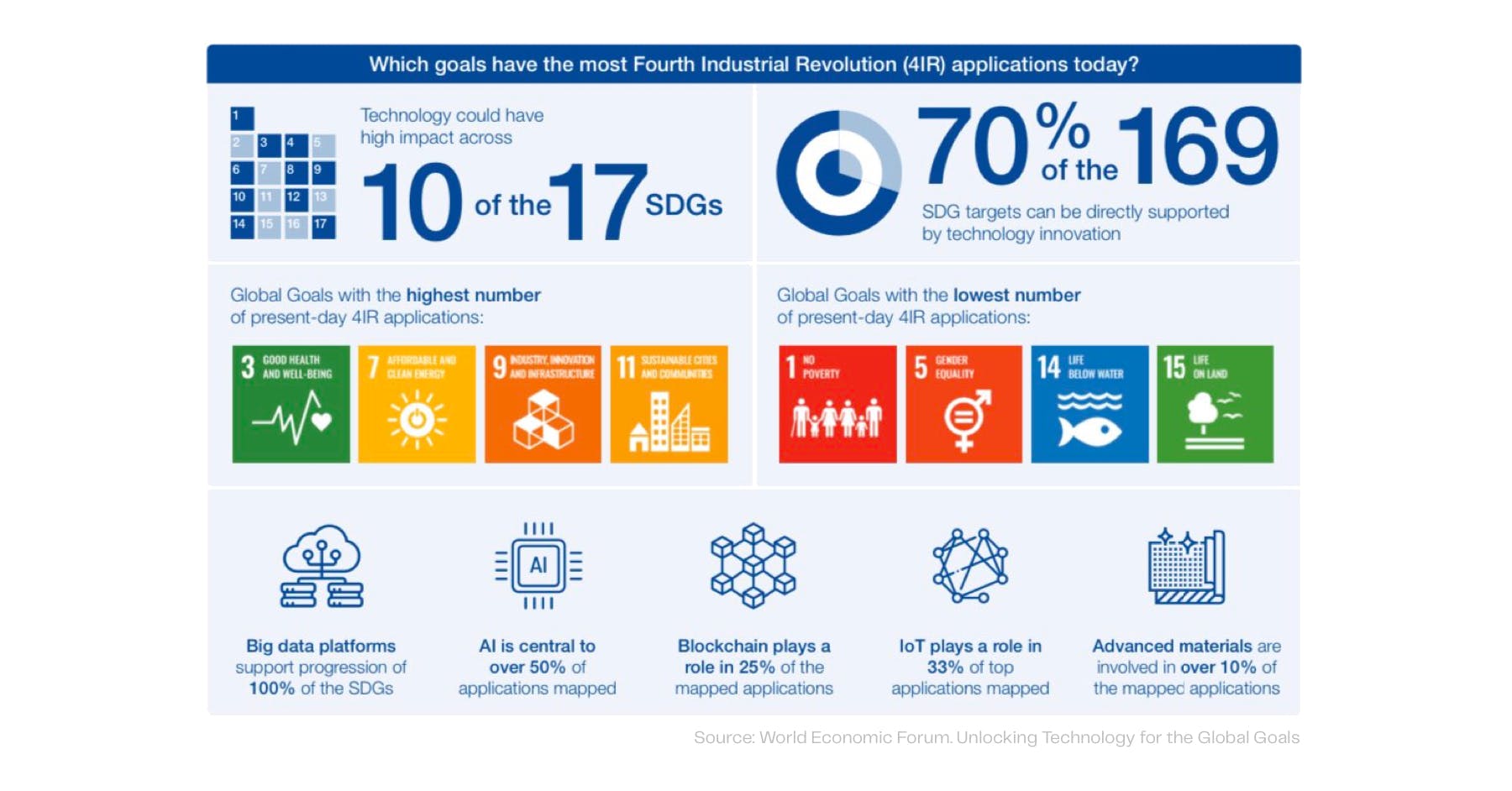

To translate the impact of IoT on a macro-scale, companies and governments adopting sustainable practices can collectively contribute and cooperate toward addressing the global Sustainable Development Goals (SDGs).

The United Nations Sustainable Development Goals are a call for action by all countries to achieve a more sustainable future for all by developing ways to protect the planet. IoT offers a way to accelerate the progress on the SDGs as solutions are easily replicable across a variety of business models.

According to the World Economic Forum’s analysis of more than 640 IoT deployments, conducted in collaboration with IoT research firm IoT Analytics, 84% of existing IoT deployments address the SDGs. What’s even more interesting is that 75% of these projects concentrate on five SDGs:

Goal #3 Good health and well-being (7%)

Goal #7 Affordable and clean energy (19%)

Goal #9 Industry, innovation, and infrastructure (25%)

Goal #11 Smart cities and communities (19%)

Goal #12 Responsible production and consumption (5%)

Businesses are using IoT to optimize systems and generate breakthrough discoveries to help tackle the SDGs. This technology-enabled, sustainable future will be driven by data and the purposeful action, collaboration, and coordination of businesses and governments alike.

Playing the Long Game with IoT-Driven Business Models

With circular economy thinking, developing an economy that doesn’t create harmful and unwanted waste makes good business sense. This kind of thinking requires manufacturers to view the resources in their products as assets rather than inputs, and their customers as users rather than buyers.

There are several well-known business models that are contributing toward the circular economy: 1) next life sales; 2) product transformation; 3) recycling 2.0; 4) product as a service; 5) and collaborative consumption.

To paint a more realistic and understandable picture of how IoT is enabling new circular models, we will focus on the latter of the two business model types - product as a service and collaborative consumption.

1: Product as a Service (PaaS)

Consumers purchase desired results rather than the asset that delivers that result. Businesses sell services that a product can provide rather than the product itself. Manufacturers own and maintain the product, and consumers lease or subscribe for its use or service. Alternatively, consumers can own the product but are not responsible for maintenance or upkeep according to licensing agreements.

2: Collaborative Consumption

Consumers have access to goods and services based on an interdependent peer-to-peer model. This enables resource circulation systems and new marketplace models, where consumers can both consume and provide products or services through direct interaction with other consumers or through a third-party application. With collaborative consumption, also known as the sharing economy, the purchase price is recouped through renting or exchanging products or services. By 2025, the impact of the sharing economy could reach around $335 billion of global revenues.

Nowadays, more businesses are looking through the lens of environmental change to prioritize business practices that promote sustainability and efficiency. Companies are continuously striving to meet the changing needs of a dynamic world as well as increasing innovation demands, all whilst aiming for the highest returns with the lowest environmental impact.

If companies were to strategically implement more IoT solutions and waste prevention measures, it could save European companies €600 billion —which is equivalent to 8% of annual turnover — while also reducing total annual greenhouse gas emissions by 2-4%.

IoT solutions prove that big data can solve big problems. Shifting toward data-driven initiatives enables businesses to become more environmentally and commercially sustainable across the entire supply chain. We are already seeing this take place with global automation and machine learning systems applied to 26% of industrial production processes, and this is just the beginning.

With the immense potential and promise of IoT, this will lead to even greater corporate innovation that can help create a better, more sustainable world.