Sustainable Supply Chains and Logistics: Navigating Transformation with IoT

In an era marked by heightened environmental consciousness and a growing understanding of the interconnectedness between business operations and ecological well-being, the concept of a sustainable supply chain and logistics has gained immense significance. This approach encompasses a range of strategies aimed at reducing the environmental impact of the entire supply chain process, from raw material extraction to the final product’s end-of-life. As businesses and consumers alike place a greater emphasis on sustainability, the landscape of supply chain and logistics has fundamentally changed in recent years. Technologies such as AI and IoT have the potential to rapidly accelerate this transformation. This article looks into the dynamics of sustainable supply chains and the pivotal role that Internet of Things (IoT) technologies play in revolutionizing this sector.

Market Insights: The Landscape of Connected Logistics

Before delving into the transformative power of IoT in sustainable supply chains, it's essential to understand the market dynamics that drive this change. The market size for connected logistics is a staggering $23.5 billion, reflecting the demand for seamless integration and real-time tracking. Inventory management, a cornerstone of efficient supply chains, accounts for $3 billion, while fleet tracking stands at an impressive $38.4 billion. These numbers underscore the urgency for businesses to optimize their supply chain processes.

In Pursuit of Seamless Operations: Traditional Supply Chain Hurdles

In today’s complex world of business, the obstacles embedded in traditional supply chains pose a multi-faceted and demanding problem. These challenges act as barriers, casting shadows on the efficiency and sustainability of supply chain operations, resulting in disruptions that impede the smooth flow of business processes. Let’s have a look at the most common hurdles in traditional supply chains:

Product Handling and Damage

Maintaining optimal temperature and humidity levels is a daunting task for traditional supply chains. Certain products, such as perishable goods and pharmaceuticals, require specific environmental conditions to preserve their quality. Failure to maintain these conditions can lead to spoilage and product wastage. Therefore, supply chain managers must invest in robust packaging, efficient handling procedures, and effective quality control mechanisms to prevent losses resulting from product impairment.

Stockouts and Overstocking

Keeping the delicate balance between supply and demand is another constant concern for companies. Stockouts occur when demand exceeds supply, leading to lost sales and dissatisfied customers. On the other hand, overstocking ties up valuable resources, increases carrying costs, and can result in product obsolescence. Achieving this balance requires advanced demand forecasting, responsive inventory management systems, and seamless communication across the supply chain network.

Transportation Breakdowns

As we painfully learned during the pandemic, transportation breakdowns pose a significant threat to the smooth functioning of a supply chain. Mechanical failures, accidents, or unforeseen incidents not only incur high costs but also result in delayed deliveries and increased downtime. Investing in a well-maintained fleet of vehicles, regular maintenance checks, and contingency plans, real-time tracking systems, and a robust network of alternative transportation options help reduce breakdowns and improve transportation reliability.

Risk of Lost or Stolen Products

In every aspect of the supply chain, from the production stage to distribution, the issue of lost or stolen products presents a significant obstacle. They do not only lead to financial losses but also undermines customer confidence. The intricate nature of modern supply chains can make it challenging to effectively track and protect products. Businesses must tackle these vulnerabilities, be it due to inadequate security measures, lapses in handling protocols, or external theft, in order to safeguard their valuable assets. To mitigate this risk and guarantee the secure transportation and storage of products, it is vital to implement robust security measures.

Suboptimal Resource Management

The lack of effective resource management for storage and transportation further compounds these challenges. Inefficient use of warehouse space and improper handling of goods can lead to unnecessary costs and errors in order fulfillment. Adopting technologies such as warehouse management systems and automated material handling equipment can optimize resource allocation and streamline operations.

When these challenges accumulate, they can have a detrimental impact on businesses. Escalated costs, diminished efficiency, and unfavorable ecological repercussions are just some of the consequences that can arise from these obstacles. By addressing these challenges head-on, businesses can enhance their supply chain performance and meet the ever-evolving demands of the market.

However, this requires proactive measures such as implementing robust security measures, investing in advanced technologies, accurate demand forecasting, and adopting agile supply chain strategies.

Unleashing Sustainability in Supply Chains for Today's Eco-Conscious Consumers

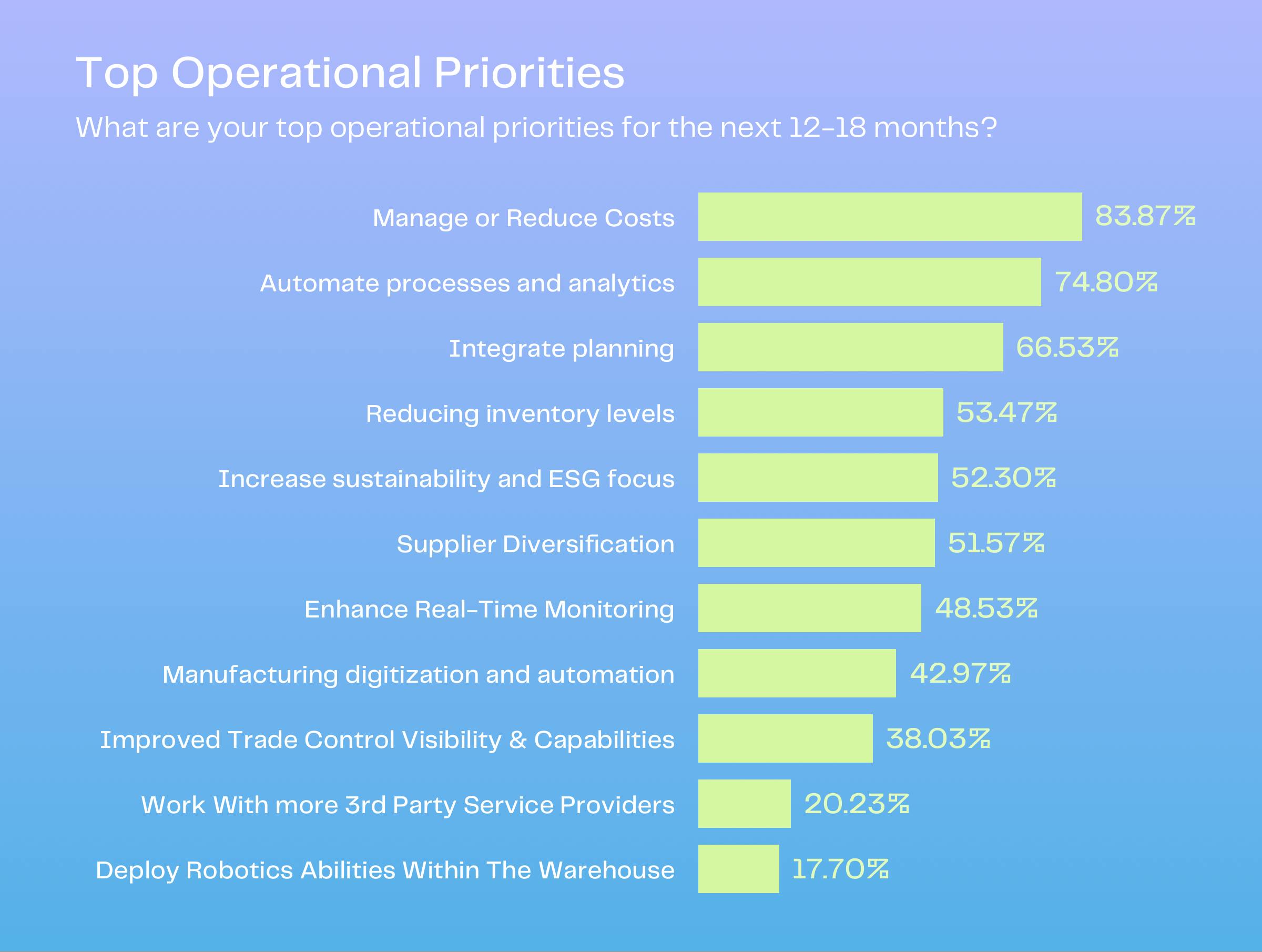

Alcott Global’s survey, “A Look at Supply Chain Priorities 2023”, revealed the priorities of companies with international operations. In addition to addressing the challenges mentioned earlier, there is now also a heightened focus on sustainability. 52 percent of respondents want to achieve long-term success by adopting sustainable practices and implementing ESG (Environmental, Social, and Governance) criteria. There is no way around it, because the issue of sustainability is becoming increasingly important for customers, investors and regulators. Therefore, companies must focus on reducing their environmental footprint and increasing their social impact in order to to remain competitive.

Transitioning to sustainable supply chains presents businesses with a range of challenges. The complexity and fragmentation of supply chain processes make it difficult to implement consistent sustainable practices at every stage. Additionally, the scarcity of resources, such as water and energy, creates a significant obstacle. Reducing greenhouse gas emissions becomes a top priority as industries aim to address their carbon footprint. Waste management and regulatory compliance further complicate the sustainability landscape.

However, amidst these challenges lie abundant opportunities that the advent of IoT technologies can unlock. The integration of IoT into supply chains can dramatically enhance safety by preventing theft and reducing accidents. Real-time monitoring of goods and assets offers complete visibility, enabling businesses to make informed decisions. Moreover, specialized supply chains, such as pharmaceuticals or high-value items, can be tracked effectively, ensuring their integrity and safety throughout the journey.

Shaping the Future of Green Supply Chain Management with IoT: Use Cases

The incorporation of IoT technology into supply chains opens up multiple use cases that directly address the challenges mentioned earlier. Let’s have a closer look at some of them.

If you yourself have an additional deep tech idea that could revolutionize the supply chain space, get in touch. As co-founders, we stand by entrepreneurs to bring their idea to life - even if they lack the technical background. Learn more about our Visionairies incubation program.

Inventory Level Tracking

By employing advanced tracking technologies with IoT sensors, businesses can automate the process of tracking inventory levels, eliminating the need for manual counting and reducing the risk of human error. Additionally, the data collected from these sensors can be analyzed to identify patterns and trends, allowing businesses to better forecast demand and plan their inventory accordingly. Monitoring inventory levels in real-time enables them to make informed decisions about production, distribution, and recycling, and provides them with significant benefits, including streamlining operations, optimizing resource utilization as well as reducing waste and carbon footprint.

Storage Optimization

Storage optimization is a vital element in a sustainable supply chain. It becomes especially crucial when products undergo multiple stages of reuse and refurbishment, as is the case on the way to a circular economy. By implementing data-driven algorithms and automated systems, storage layouts can be optimized to ensure that available space is utilized efficiently, while still maintaining the integrity of the products. Smart sensors can monitor storage conditions, such as temperature and humidity, ensuring that products are kept within optimal ranges. This mitigates the risk of spoilage and maintains product quality.

This approach enables businesses to achieve a more productive storage process, ultimately contributing to a more sustainable and cost-effective supply chain.

One aspect of storage optimization is warehouse automation. Retailers invested a significant amount of $2.5 billion in 2020 for the purchase and installation of updated IoT hardware.

In 2019, the rate of technology adoption in this segment was merely eight percent. It is projected to increase significantly and reach 45 percent by the year 2030.

Theft Protection

As previously mentioned, theft and product loss are two major issues that can have a significant impact on a company’s bottom line and overall operations.

One such strategy is the adoption of IoT-enabled security measures into the supply chain to enhance security and monitoring capabilities. GPS tracking, for example, allows companies to track the location of their products in real-time, making it easier to identify any unauthorized access or potential theft. Another IoT-enabled security measure is the use of RFID (Radio-Frequency Identification) tagging, enabling companies to quickly identify any discrepancies or irregularities in product shipment and safeguard their products throughout the supply chain.

Lastly, secure storage facilities play a crucial role in preventing unauthorized access and product pilferage. These facilities should be equipped with robust security systems, including surveillance cameras, access control systems, and alarm systems. By ensuring that products are stored in secure facilities, companies can minimize the risk of theft and loss.

Logistics Optimization

Logistics, the backbone of a sustainable supply chain, is an essential component that ensures smooth and efficient movement of goods. By incorporating advanced, IoT based technologies such as route optimization software, predictive maintenance for vehicles, and real-time tracking systems, the transportation process becomes more streamlined and optimized.

These cutting-edge tools not only enhance the efficiency of the supply chain but also minimize delays, allowing products to reach their intended destinations in a timely manner. Moreover, these innovative measures play a vital role in identifying bottlenecks and inefficiencies within logistics operations, enabling companies to make data-driven decisions for continuous improvement and increased productivity.

Supply Chain Tracking and Analysis

Inefficient digital technologies in their supply chains were a challenge for 85 percent of the respondents, as a McKinsey study found out. IoT has transformed the manner in which businesses monitor and oversee their supply chains, bringing about a wave of innovation and efficiency. Through the utilization of cutting-edge tracking and analysis tools, companies are able to obtain a comprehensive, all-encompassing perspective of their supply chain operations.

This visibility empowers them with invaluable insights into the overall performance of their supply chain, enabling them to make well-informed decisions based on concrete data and subsequently drive continuous improvements throughout the entire process. The result are smarter, more resilient and more sustainable supply chains.

Driver Behavior and Monitoring

Monitoring driver behavior can have a profound and far-reaching impact on both efficiency and safety. By implementing driver monitoring systems, fleet managers can gain crucial insights into driver behavior, allowing them to make more informed decisions and take appropriate actions to improve performance, enhance safety measures, and ultimately save lives on the road. With the ability to track factors such as fuel consumption, driving habits, and vehicle maintenance, businesses can optimize delivery routes, reduce fuel consumption, and contribute to the creation of a more sustainable and environmentally friendly supply chain.

Food and Beverage Supply Chain

For perishable goods like food and beverages, IoT-enabled temperature and humidity monitoring ensures that products remain fresh and safe throughout the supply chain journey. Cold chain management, precise demand forecasting, and efficient distribution networks are essential components in ensuring the freshness and quality of food and beverages as they move through the cycle.

Apart from that, such a sustainable supply chain is crucial for minimizing food waste. According to UN Food and Agriculture Organization (FAO), one third of food produced for humans is wasted. Product quality factors often arise within the first 24 to 48 hours after harvest due to various issues such as harvest conditions, temperature management, logistics, and handling variations.This is not only expensive - the UN says it costs more than $400 billion per year all while 800 million people go hungry – but also harms the environment: greenhouse gases resulting from food waste contribute to nearly half of all global food system emissions.

Managing Specialized Supply Chains

Certain industries, like pharmaceuticals and electronics, require specialized handling and storage conditions. Managing a circular supply chain in these sectors involves maintaining strict temperature controls, humidity levels, and other environmental factors to ensure product integrity throughout the lifecycle. IoT sensors such as those from the Icelandic specialist for pharma supply chains Controlant measures these critical values and transmits them to a platform that provides real-time evaluations. Through excursion notifications and quality reports, Controland provides its customers with vital data for conducting inspections, supporting informed decision-making, and prompt intervention.

Embracing the Future of Sustainable Logistics

In conclusion, the transformation of supply chains and logistics into sustainable entities is no longer an option but a necessity. The challenges are substantial, but the opportunities are equally promising. By harnessing the power of IoT, businesses can mitigate risks, optimize operations, and contribute positively to environmental conservation. From inventory tracking to specialized supply chains, IoT technologies have the potential to revolutionize every aspect of the supply chain landscape.